Liquid tank filter is mainly used to filter the end of 0.3um clean room and purification equipment, control particles and microorganisms larger than 0.3um in clean room or equipment working area, widely used in the pharmaceutical industry, suitable for on-site PAO leak detection test.

Performance characteristics

Using two-component polyurethane gel perfusion, good sealing performance;

There are top liquid tank, side liquid tank, double liquid tank and other structure choices;

According to the requirements of the selection of glass fiber materials, PTFE materials;

Optional: aluminum profile, stainless steel frame.

Materials and conditions of use

Outer frame | Aluminum alloy, galvanized sheet, stainless steel |

Filter material | Fiberglass,PTFE |

Divider | Hot melt glue |

Filtration efficiency | H13、H14、U15、U16 |

Seal | Polyurethane sealant |

Operating temperature | ≤80℃ |

Final resistance | <450Pa |

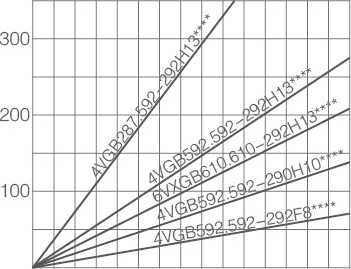

Curves of air volume and resistance characteristics

Technical parameter

Overall dimension (mm) | Rated air volume (m3/h) | Initial resistance(Pa) | Dust capacity (g) |

99.95~99.995% | 99.95~99.995% |

592x592x292x4V | 2400 | ≤220 | ≤250 | 2000 |

592x592x292x5V | 3000 | 2500 |

592x287x292x5V | 1500 | 1250 |

592x287x292x4V | 1200 | 1000 |

610x610x292x5V | 3400 | 3000 |

610x610x292x4V | 3000 | 2000 |

305x610x292x2V | 1200 | 1000 |